Materials and Results

The degree of hardness depends on the chemical analysis of the metal, with carbon being the principal controlling element. When heating and quenching rates are accurately controlled, any ferrous material which can be furnace hardened can be flame hardened to a higher degree of hardness. In choosing a material, availability, cost, hardness and machinability are factors to consider. Our technical staff can advise and discuss specific applications. Effects of flame hardening on steel and iron

| Steel/Iron Type | Hardness, Rockwell C |

|---|---|

| 1020 mild steel 8620 carburised 1045 | 30 – 40 62+ 55 – 60 |

| 1145* 1060 4140 | 55 – 60 62+ 52 – 58 |

| 4150 6150 52100 | 58 – 62 58 – 62 55 – 62 |

| Hardenable martensitic stainless steel Pearlitic cast iron (Ductile and grey) | 50 – 60 50 – 60 |

* Fatigue proof, stress proof

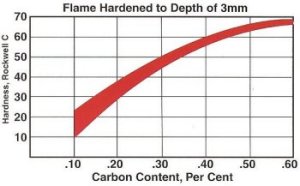

Hardness range of plain carbon steels

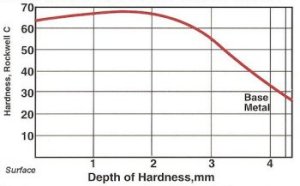

Typical hardness curve for flame hardened medium carbon steels.

| Rockwell C | Scleroscope | 10mm Steel Ball (HB) |

|---|---|---|

| 66 65 64 | – – – | 701 86 671 |

| 63 62 61 | 84 82 81 | 656 642 628 |

| 63 62 61 | 84 82 81 | 656 642 628 |

| 60 59 58 | 80 78 77 | 613 600 584 |

| 57 56 55 | 76 74 73 | 574 561 548 |

| 54 53 52 | 71 70 69 | 536 524 512 |

| 51 50 49 | 67 66 65 | 500 488 476 |

| 48 47 46 | 63 62 61 | 464 453 442 |

| 45 44 43 | 59 58 57 | 430 419 408 |

| 42 41 40 | 56 54 53 | 398 387 377 |

| 39 38 37 | 52 51 50 | 367 357 347 |

| 36 35 34 | 48 47 46 | 337 327 318 |

| 33 32 31 | 45 44 43 | 309 301 294 |

| 30 29 28 | 42 41 40 | 286 279 272 |

| 27 26 25 | 39 38 37 | 265 259 253 |

| 24 23 22 | 36 36 35 | 247 241 235 |

| 21 20 | 34 33 | 230 220 |