Metal heat treatment options by Alpha Detroit Heat Treatment provide specialised services for both annealing and normalising, delivering quality results.

Metal heat treatment options directly influence a material’s microstructure, impacting its physical and mechanical properties. Controlled heating and cooling cycles manipulate grain size and phase distribution, resulting in targeted strength and ductility. Proper application of these techniques ensures components meet specific performance criteria, extending service life and enhancing reliability.

Comparing Metal Heat Treatment Options: Annealing vs. Normalising

Annealing, a method that involves heating metal to a predetermined temperature followed by slow cooling, aims to produce a material with maximum softness and ductility, thus minimising internal stresses. Normalising, in contrast, applies a similar heating phase but introduces air cooling, leading to a finer grain structure and a product with increased hardness and tensile strength compared to the annealed counterpart. The choice between these methods hinges on the intended application and the desired balance of material properties.

The fundamental difference lies in the cooling rate: a slow, controlled cooling in annealing versus a faster, air-based cooling in normalising. This variation dictates the resulting microstructure and, consequently, the mechanical behaviour of the metal. Consequently, components requiring high formability and minimal residual stress benefit from annealing, while those demanding increased strength and toughness are better suited for normalising.

Annealing in Metal Heat Treatment Options: A Process for Softening

The strategic application of thermal treatments, specifically annealing, facilitates the manipulation of dislocation densities and grain boundary energetics within metallic matrices. This methodology induces a quantifiable reduction in residual stress states, concurrently promoting grain coarsening, thereby enhancing macroscopic ductility.

Controlled thermal cycling regimens, inclusive of annealing protocols, are implemented to optimise machinability and mitigate deleterious residual strain fields. These procedures affect a reduction in shear force requirements during material removal, and concurrently refine microstructural homogeneity, resulting in enhanced consistency of mechanical properties.

Normalising in Metal Heat Treatment: Enhancing Strength and Uniformity

Normalising addresses essential structural and mechanical enhancements in metals through controlled thermal processing. Specific microstructural changes brought about by this method are vital for achieving desired performance characteristics.

• Refined Grain Structure: A finer grain size, achieved through normalising, increases grain boundary density, effectively impeding dislocation movement and elevating yield strength. This leads to improved resistance against fracture and fatigue.

• Homogenised Microstructure: Normalising eliminates dendritic segregation, resulting in a uniform distribution of alloying elements and phases, which enhances mechanical property consistency. This ensures predictable material responses under various stress conditions.

• Enhanced Tensile Strength: By refining the grain structure and reducing internal stresses, normalising increases the material’s ability to withstand tensile forces. This is vital for applications requiring significant load-bearing capabilities.

• Reduced Internal Stresses: Residual stresses from prior manufacturing are alleviated through normalising, preventing distortion and premature failure in service. This stress reduction contributes to dimensional stability and extended component lifespan.

Optimising Material Performance Through Strategic Thermal Processing

The selection and execution of appropriate thermal processing techniques, such as annealing and normalising, dictate the final mechanical properties of metal components. Alpha Detroit Heat Treatment provides a detailed analysis of required material properties to determine the ideal heat treatment process. We prioritise material integrity and performance, offering comprehensive heat treatment solutions.

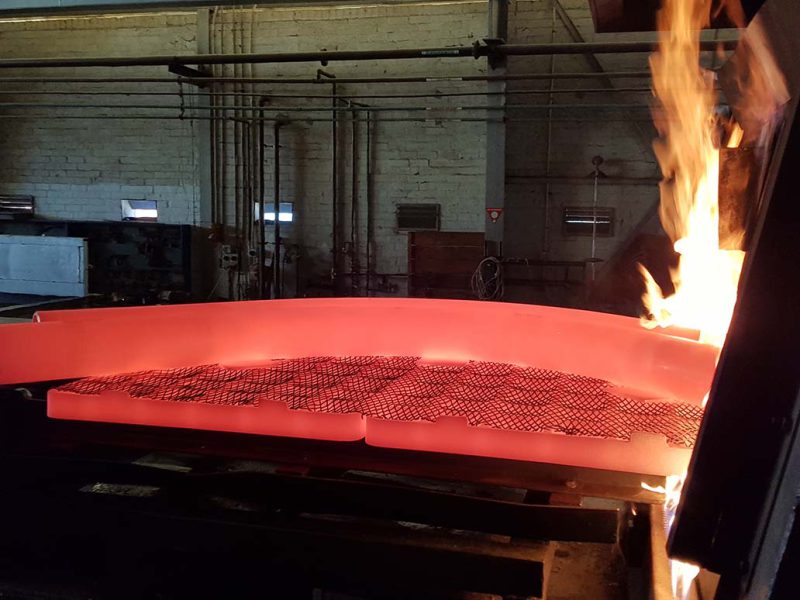

Browse our gallery and see the precision and expertise we bring to every project.

Read our blog for more information: How a Heat Treatment Modifies Metal Properties

Related Concept: Annealing vs. Normalizing: Contrasts, Benefits, and Applications

Optimized by: Netwizard SEO