Flame Hardening Services by Alpha Detroit: Enhancing Dies and Moulds

01 November 2023

Elevate the durability of dies and moulds through flame hardening services by Alpha Detroit. Boost the performance of these components. Call (03) 9555 3682.

The durability and longevity of critical components like dies and moulds are highly important, especially in the world of industrial manufacturing. To meet the demands of rigorous production environments, they must be subjected to techniques like flame hardening. Flame hardening services can be maximised by manufacturing sites as they can enhance the hardness and wear resistance of these components, which then improve their performance and service life.

Flame Hardening: The Working Principles

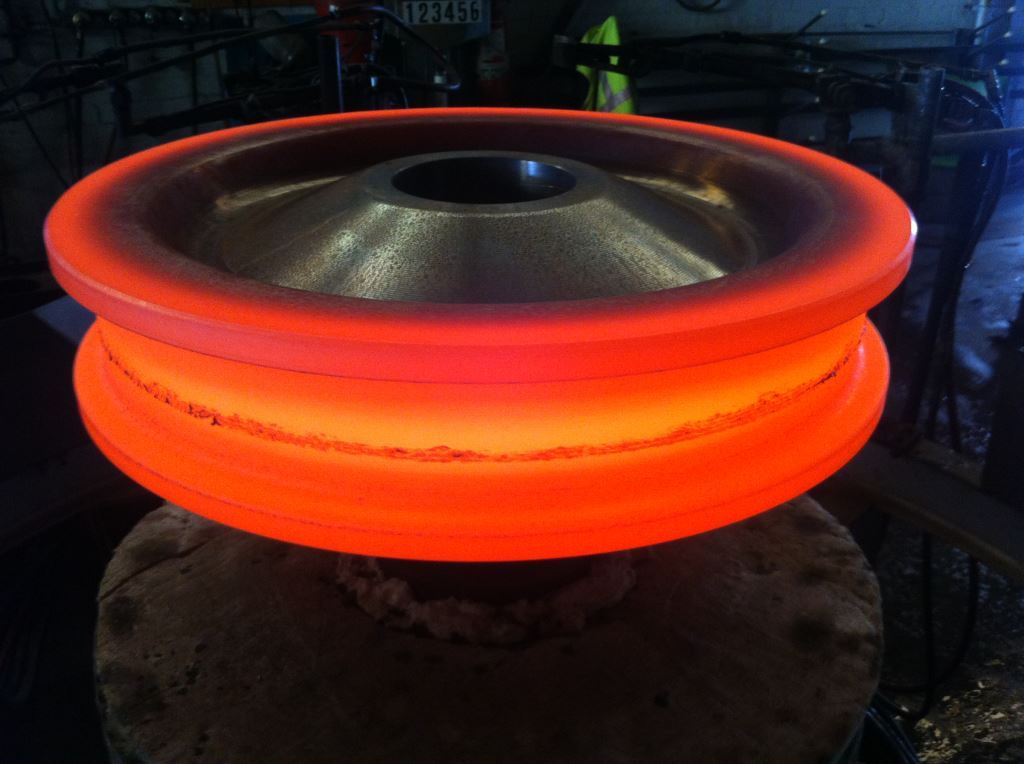

Flame hardening is a heat treatment process that aims to improve the hardness of specific areas of a metal component. During this process, a focused flame is applied to the surface of the component, rapidly heating it to a critical temperature. The component is subsequently quenched or cooled rapidly, causing the surface to harden while retaining the core’s toughness.

Now, before carrying out these steps, the component’s surface must be cleaned and prepared first to ensure optimal heat transfer during flame hardening. Tempering, in some cases, must then be carried out after flame hardening to reduce internal stresses and further enhance the mechanical properties of a component.

The whole process of flame hardening can be useful on components like gears, shafts, pins, and other industrial parts that require enhanced wear resistance and hardness. It is especially effective when precise control over the treated areas is needed.

Alpha Detroit’s Flame Hardening Services

As for your dies and moulds, subjecting them to our flame hardening services at Alpha Detroit can help you gain the following benefits.

• Enhanced Wear Resistance: Dies and moulds often come into contact with abrasive materials during manufacturing processes. Flame hardening can generate a hardened surface layer that resists wear and reduces the need for frequent replacements.

• Increased Hardness: The selectively hardened surface of dies and moulds exhibits higher hardness values, which then ensures the component’s ability to withstand mechanical stress, impact, and abrasive forces.

• Improved Dimensional Stability: Flame hardening can likewise minimise distortion and warping on dies and moulds, preserving their dimensional accuracy and contributing to consistent and precise manufacturing.

• Boosted Energy Efficiency: Compared to full-scale heat treatment processes, flame hardening is energy-efficient since it targets only the required areas for hardening, conserving resources and minimising environmental impact.

• Customisable Treatment: Flame hardening then allows for precise control over the depth and pattern of hardened areas, making sure that only specific regions critical to the component’s function undergo the process.

• Extended Service Life: By improving wear resistance and hardness, flame hardening can effectively extend the operational life of dies and moulds, which reduces their downtime and replacement costs.

Our flame hardening services find application in a wide range of industries, including automotive, aerospace, tool and die manufacturing, and more. Dies used in metal forming, extrusion, and forging benefit from improved wear resistance, while moulds in plastics and rubber processing can attain enhanced durability.

At Alpha Detroit, our flame hardening services can easily bring a precision-focused solution to enhance the durability and performance of critical industrial components like dies and moulds. By selectively improving the hardness and wear resistance, our heat treatment process can contribute to reducing downtime, increasing efficiency, and gaining cost savings, making it a valuable investment for your high-performance manufacturing processes.

Optimized by: Netwizard SEO