- Induction Hardening

- Flame Hardening

- Vacuum Heat Treatment

- Case Hardening and Carbonitriding

- Hardening, Annealing and Tempering

- Stress Relieving

- Nitriding

- Non Ferrous Heat Treatment

- Precision Straightening

- Black Oxide Coating

Induction Hardening

For high precision induction hardening, a vertical induction scanner is ideal for hardening a wide range of pins, axles, shafts and rollers. Hardness depths up to 15mm can be achieved.

Dimensions: Max parts diameter 175mm, Max length 1800mm

Flame Hardening

Why Flame Hardening Will Save You Money

Flame hardening is a reliable and time proven alternative to other types of heat treatment and the savings can be tremendous.

Flame hardening will save you money and help increase profits, because it…

- gives higher hardness for increased life

- provides more efficient productivity

- reduces downtime and maintenance costs

- hardens selected areas only

- reduces costs because of less coverage

- less distortion

- less machining and grinding, and

- less processing time

Rolls and Shafts

Rolls and Shafts

Flame hardening is the best and sometimes the only way to heat treat large rolls.

- Minimum distortion and higher surface hardness is combined with ductilitiy and core strength.

- The ‘progressive spin’ method ensures a uniform hardness over the entire roll surface.

- We can flame harden rolls up to 1000mm in diameter.

Sheaves, Rope Drums and Slew Rings

Flame hardening dramatically reduces wear on load bearing rope groove areas and bearing surfaces on slew rings and thrust bearings.

We Can Perform Full or Partial Groove Area Hardening.

Lifting Capacity 20 Tonnes

Machine Ways and Rails

Today’s modern flexible machining systems and automated transfer lines have many flame hardened components, including

- Replaceable Ways

- Fabricated Basesmachine Ways and Rails

- Precision Guide Rails

- Cast Beds and Pallets

Whatever your needs, we have the experience to process these parts for optimum results.

Dies and Moulds

Flame hardening of dies and moulds reduces wear and increases die life.

Large automotive dies provide ideal examples of the proper application of flame hardening and can be handled as readily as small ones.

Smaller dies may require hardening of shut-off or runner areas only. Instead of buying new dies, flame hardening allows the reworking of old dies by making shape modifications and re-flame hardening.

Dies can be finished and tried out before they are finally flame hardened for production runs.

The flame hardened areas are usually adjacent to the die working faces so there is a minimum of heat exposure which eliminates distortion.

Applications

- Plastic mould dies

- Metal stamping, blanking, forming and shearing dies

Suitable materials

- Alloy steels

- Plain carbon steels

- Ductile iron

- Cast iron

- Stainless steels

Gears and Sprockets

Replacement of worn gears can be expensive, time-consuming and difficult.

Increase the life of gears, sprockets and gear racks with flame hardening.

By only hardening the wear areas of the gears, the base metal keeps its original tensile strength.

Spin or progressive hardening available.

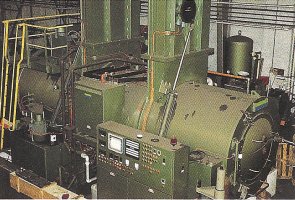

Vacuum Heat Treatment

- Two vacuum furnaces

- A three-chamber vacuum furnace incorporates an oil quench facility as well as a fan forced gas quench

- Programmable logic controls on both heating and quench cycles ensures optimum heat treatment conditions for a wide range of material, including;

- hot and cold work tool steels

- plastic mould steels

- stainless steels

- high speed steels

- low alloyed steel

Max dimensions: L 1000mm, W 610mm, H 760mm

Case Hardening and Carbonitriding

- Three sealed-quench furnaces with endothermic atmosphere

- Salt pot case hardening

- Pack-carburising case hardening

- Carbonitriding

All processes can provide heavy and light case depth carburising

Sealed quench furnaces max dimensions: L 1300mm, W 770mm, H 610mm

Salt pot max dimensions: 560mm deep, 480mm diameter

Hardening, Annealing and Tempering

General through-hardening, normalising and tempering of small or large components is possible in our atmosphere-controlled stress relieving furnaces or large bogie hearth furnace.

- oil hardening steels

- air hardening steels

Max dimensions: L 3800mm, W 1400mm, H 1500mm

Anealing

Components requiring annealing can be processed in one of our vacuum-sealed quench or bogie hearth furnaces, depending on the size of the component and the surface finish required.

Stress Relieving

Stress Relieving and Hydrogen De-embrittlement

Bogie Hearth Furnace

- Natural gas fired furnace

- Uniform temperature maintained by four independently controlled, variable speed burners

- Hydrogen de-embrittlement

- Lifting capacity of 20 tonnes

- Stress relieving applications

- weldments and fabrications

- roughed out dies, flats and rounds

- highly stressed extruded and rolled stock materials

- castings

- flame or laser cut profiles and plates

Max dimensions: L 3800mm, W 1400mm, H 1500mm

Nitriding

The Alpha Heat Treatment standard nitriding process uses a controlled gas atmosphere incorporating a diffusion stage.

This eliminates the detrimental effects of the ‘white layer’ which occurs in conventional nitriding processes.

- Two nitriding furnaces

- Controlled gas atmosphere

- Diffusion cycle

Max dimensions: Diameter 850mm, Depth 1980mm

Non Ferrous Heat Treatment

- Copper and its alloys

- bright annealing (vacuum furnace)

- ageing of phosphor bronze

- Aluminium and its alloys

- stress relieving of weldments and castings

- solution treatment and ageing

- Vacuum heat treatment of precious metal electrical components

Precision Straightening

- A range of straightening presses up to 20 tonne capacity

- Both ‘cold’ and ‘hot’ precision straightening to commercial grinding tolerances

- Remove twists with a specially adapted ‘detwisting’ press

Press dimensions: W 1100mm, H 700mm

Black Oxide Coating

This coating gives a great looking black finish, combined with excellent protection against rust.

Our ‘hot liquid bath’ process is also long lasting and very durable, even when parts are subjected to flexing.

We offer a 24 hour service. Faster turnarounds can be arranged.

Maximum dimensions: Diameter 450mm, Length 500mm

Architectural Blackening

At Alpha Detroit Heat Treatment we can also blacken large architectural pieces by hot dipping steel into quenching oil.

Although not as good a coating as the authentic black oxide coating, it results in a slightly uneven mottled blackened look which appeals to some customers for a non-corrosive environment, giving a rustic blackened appearance.

Maximum dimensions: Length 3,000mm, Width 1,150mm, Height 1,350mm