Vacuum heat treatment by Alpha Detroit improves the durability of precious metal electrical components in Australia and New Zealand, optimising quality.

Vacuum heat treatment is a specialised process that enhances the performance and durability of precious metal electrical components, making it essential for industries requiring high-quality, long-lasting parts. Offered by Alpha Detroit in Australia and New Zealand, this advanced heat treatment method improves component strength, conductivity, and resistance to wear.

Vacuum Heat Treatment: Working Principles

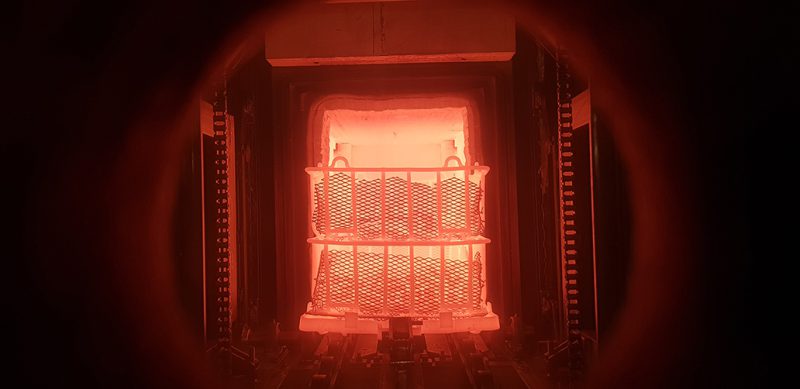

Vacuum heat treatment is a specialised thermal processing technique used to alter the physical and chemical properties of materials, particularly metals and alloys. This process involves heating materials in a vacuum environment to reduce or eliminate the presence of oxygen and other reactive gases that can lead to oxidation or contamination.

During vacuum heat treatment, the material is placed in a vacuum chamber, which is then evacuated to remove air and other gases. Once a vacuum is achieved, the material is heated to a specific temperature, often above its recrystallisation temperature. This heating process can last for a predetermined duration, depending on the material and desired properties.

After the heating phase, the material may be cooled rapidly, often by quenching in a liquid or using controlled cooling methods within the vacuum chamber. The cooling process is critical for achieving the desired microstructure and mechanical properties.

Processing Metal Electrical Components

In manufacturing precious metal electrical components, vacuum heat treatment can be maximised since it can optimise production and enhance the performance of the said workpieces.

Precious metals, such as gold, silver, and platinum, are often used in electrical applications due to their excellent conductivity and resistance to corrosion. However, to achieve optimal performance and longevity, these materials require careful thermal processing.

Here’s how vacuum heat treatment plays a role in this optimisation.

• Enhanced Material Properties: Subjecting precious metal components to controlled heating and cooling in a vacuum allows manufacturers to enhance their hardness, strength, and overall durability. This is particularly important for electrical components that must withstand wear and maintain conductivity over time.

• Reduction of Oxidation: Vacuum heat treatment effectively eliminates the risk of oxidation on precious metals by creating a controlled environment free from such contaminants. This results in cleaner surfaces, improved conductivity, and minimal need for post-treatment finishing.

• Uniform Heating and Cooling: Vacuum heat treatment can likewise ensure uniform temperature distribution throughout the material. This consistent heating and cooling process is vital for achieving homogeneous microstructures, contributing to better mechanical properties.

• Improved Surface Quality: The vacuum environment prevents the formation of oxides and other surface imperfections that can occur during traditional heat treatment. This improved surface quality is critical in electrical applications since surface integrity can impact conductivity and performance.

• Environmentally Friendly Approach: Vacuum heat treatment is considered more environmentally friendly compared to traditional methods, as it reduces the need for harmful chemicals and generates less waste. This aligns with the growing industry’s emphasis on sustainability and responsible manufacturing practices.

Vacuum heat treatment is essential for optimising the production of precious metal electrical components. By enhancing material properties, reducing oxidation, ensuring uniform heating, and improving surface quality, this process contributes significantly to the performance and reliability of these components.

If you want to subject your precious metal electrical components to vacuum heat treatment, contact Alpha Detroit Heat Treatment today!

Optimized by: Netwizard SEO