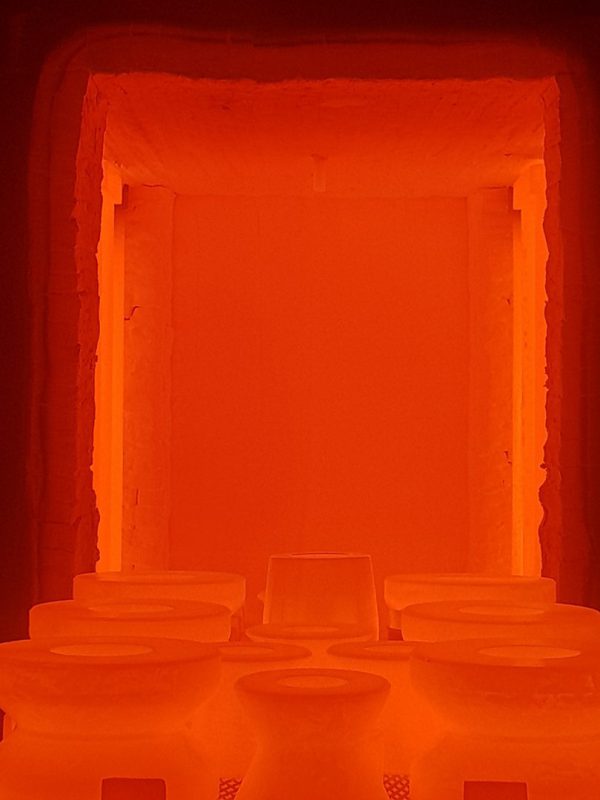

Vacuum heat treatment has redefined precision metallurgy by enabling decarb-free, high-performance tooling. This advanced thermal process is ideal for stainless steels requiring exact hardness, minimal distortion, and pristine surface finish. By eliminating atmospheric contamination, it ensures consistency and structural integrity across every component.

Decarb-Free Surfaces Through Controlled Vacuum Environments

Maintaining chemical composition during heat treatment is critical for tool performance. The controlled, oxygen-free atmosphere in a vacuum furnace prevents carbon depletion and oxidation, ensuring clean, consistent results.

Key technical advantages include:

• Zero surface oxidation: The vacuum chamber eliminates oxygen exposure, preventing scale formation and preserving a bright, metallic surface finish.

• Accurate carbon retention: The sealed environment maintains the alloy’s carbon content, ensuring optimal hardness and wear resistance throughout the tooling.

• Dimensional precision: Uniform heating and cooling cycles minimise distortion, producing geometrically stable components ready for immediate application.

• Enhanced microstructural uniformity: Even heat distribution refines the grain structure, resulting in predictable mechanical properties and superior fatigue resistance.

• Reduced post-treatment finishing: Smooth, clean surfaces reduce or eliminate the need for polishing or grinding, saving both time and cost.

This process guarantees each stainless or alloy tool maintains its original specifications, delivering high strength and repeatable performance under demanding conditions.

Advanced Cooling Control in Vacuum Heat Treatment

Controlled cooling is central to maintaining metallurgical balance. Vacuum heat treatment systems use inert gas quenching, typically with nitrogen or argon, to achieve precise hardness levels without thermal shock or structural stress. Programmable temperature profiles enable accurate transformation of the steel’s microstructure, improving durability and resistance to deformation.

The research on the Development and Prospect of Vacuum High-Pressure Gas Quenching Technology highlights that high-pressure gas quenching in vacuum furnaces enhances heat transfer efficiency and minimises thermal gradients during cooling. This study further confirms that controlled quenching atmospheres significantly reduce distortion and improve the uniformity of mechanical properties. Compared to conventional methods, this advanced vacuum technology provides greater consistency, reduced energy consumption, and significantly fewer rejects caused by dimensional inaccuracies.

Why Manufacturers Choose Alpha Detroit Heat Treatment

Our team at Alpha Detroit Heat Treatment specialises in vacuum heat treatment for stainless tooling and complex alloys. Our modern vacuum furnaces ensure decarb-free, distortion-controlled outcomes, supported by advanced testing for hardness, microstructure, and dimensional compliance.

Our technical expertise ensures each batch meets precise client specifications for tool steels, dies, and moulds used in critical manufacturing sectors such as aerospace, medical, and defence.

Enhance Tooling Performance with Decarb-Free Results

Decarb-free finishes achieved through vacuum processing deliver unmatched precision, surface quality, and longevity. At Alpha Detroit Heat Treatment, we provide stainless tooling solutions that maintain their integrity under the most demanding conditions.

Contact us today to discuss your production requirements and experience the reliability and precision of our vacuum furnace technology.

Related Blog Article: Precision Vacuum Heat Treatment Services – Australian-Based, Tight Tolerance Guarantee

Optimized by: Netwizard SEO