Discover the transformative power of vacuum heat treatment in advanced material processing. Uncover its impact on material properties. Call (03) 9555 3682.

To manufacture and treat materials, they must undergo advanced material processing. It covers sophisticated techniques, technologies, and methodologies to manufacture and treat materials, helping manufacturers achieve the desired properties, characteristics, and functionalities of their parts and components. This field encompasses a wide range of processes applied to metals, ceramics, composites, and many more, ensuring they gain improved mechanical, chemical, and other properties.

One process that can be useful in advanced material processing is vacuum heat treatment.

Key Principles of Vacuum Heat Treatment

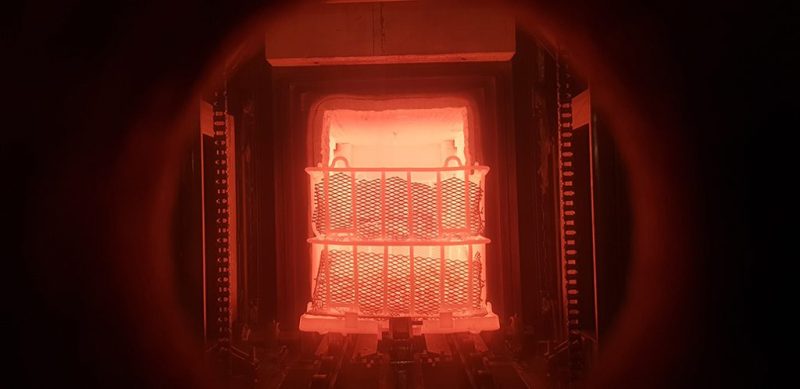

Vacuum heat treatment is a specialised thermal process that involves subjecting materials to elevated temperatures in a vacuum environment, devoid of air and other reactive gases. This controlled atmosphere prevents undesired reactions, such as oxidation and decarburisation, allowing for precise control over the heat treatment process. The absence of contaminants ensures that the material undergoes a clean and controlled transformation.

This process takes place in a vacuum furnace, which is designed to create a low-pressure environment by removing air and other gases. The materials or components to be treated are loaded into the said furnace which is later heated to the desired temperature. Once the desired temperature is reached, the materials are held at that temperature for a specific duration to reach a uniform temperature throughout.

After the soaking period, the materials are cooled down. Some vacuum heat treatments, however, involve quenching. It can be done using various methods like gas quenching or oil quenching.

Purpose in Advanced Material Processing

Advanced material processing can take advantage of vacuum heat treatment as it can carry out the following notable purposes.

• Enhance Mechanical Properties: One of the primary purposes of vacuum heat treatment is to enhance mechanical properties in materials. It can modify characteristics such as hardness, strength, and toughness, leading to materials better suited for specific applications.

• Improve Thermal Stability: Thermal stability is a critical consideration for materials used in high-temperature environments. Vacuum heat treatment can significantly improve the thermal stability of materials by refining their microstructure, resulting in materials that can withstand elevated temperatures without undergoing detrimental changes.

• Achieve Homogeneous Microstructures: The controlled environment of vacuum heat treatment ensures uniform heating and cooling throughout the material, leading to homogeneous microstructures. This uniformity is essential for achieving consistent material properties across the entire component. Whether it’s eliminating residual stresses or refining grain structures, the result is a material with predictable and reliable characteristics.

• Minimise Distortion and Residual Stresses: Distortion and residual stresses are common challenges in heat treatment processes. Vacuum heat treatment mitigates these issues by providing a uniform and controlled environment. The absence of reactive gases reduces the likelihood of distortion, and the controlled cooling process minimises residual stresses, ensuring that the final component maintains its dimensional integrity.

Vacuum heat treatment, which can be done by Alpha Detroit Heat Treatment, provides a precise and controlled environment for the transformation of materials. Its primary purposes make it a significant step in the production of high-performance components that can be useful in industries such as aerospace, automotive, medical manufacturing, and many more.

Optimized by: Netwizard SEO