Explore the benefits of nitriding services for enhanced corrosion protection and discover how Alpha Detroit can elevate the performance of your metal components.

Corrosion, the deterioration of metal surfaces due to chemical reactions with their environment, is a persistent enemy in countless industries. From everyday household items to critical infrastructure components, corrosion can lead to costly repairs, safety hazards, and product failures. But, there’s a reliable solution: Nitriding services by Alpha Detroit.

What is Nitriding?

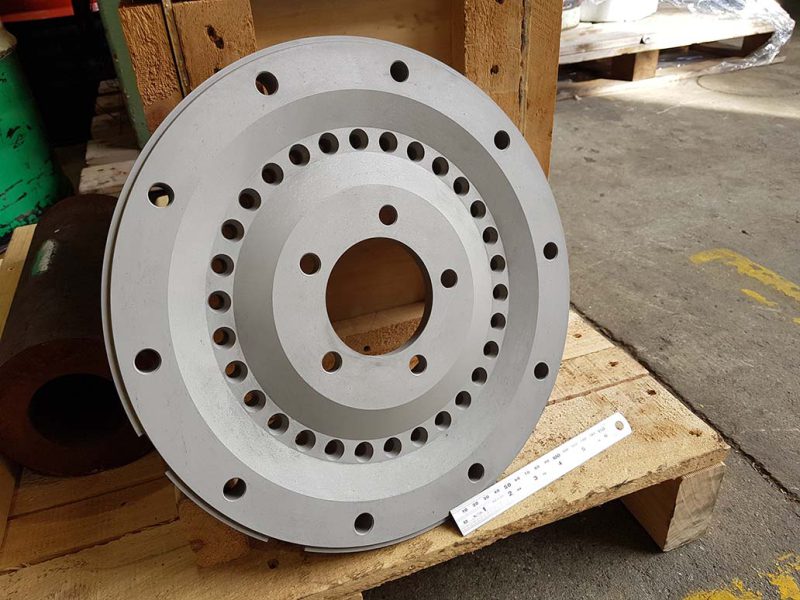

Nitriding is a thermochemical heat treatment process that diffuses nitrogen atoms into the surface of a ferrous metal object. This creates a hardened, wear-resistant, and exceptionally corrosion-resistant layer known as a nitride case. Alpha Detroit, a leading provider of nitriding services in Australia, utilises this technology to enhance the performance and lifespan of various metal components.

Nitriding’s Advantage: Superior Corrosion Protection

Compared to traditional surface treatments like painting or galvanising, nitriding offers unmatched protection against corrosion. Here’s why:

• Diffusion Bonding: Unlike coatings that adhere to the surface, the nitride case becomes an integral part of the metal through diffusion. This creates a superior bond that’s far less susceptible to peeling or flaking, even under harsh conditions.

• Enhanced Barrier: The nitride case acts as a robust barrier, hindering the interaction between the metal and corrosive elements like oxygen, moisture, or specific chemicals encountered in different applications.

• Improved Passivity: Nitriding can also passivate the metal surface, making it less reactive and further inhibiting corrosion. This is particularly beneficial for applications where components are exposed to saltwater or acidic environments.

Benefits Beyond Corrosion Protection

While superior corrosion resistance is a primary benefit, nitriding offers additional advantages:

• Increased Wear Resistance: The nitride case significantly enhances a component’s resistance to wear and tear. This translates to longer component lifespans, reduced maintenance requirements, and improved overall product performance.

• Enhanced Fatigue Strength: Nitriding improves a metal’s fatigue strength, meaning it can withstand repeated stress without failure. This is crucial for components subjected to constant cyclical loading, such as gears, shafts, and springs.

• Improved Surface Hardness: The nitriding process results in a harder surface layer, making components more resistant to scratches, dents, and other forms of mechanical damage.

Why Choose Alpha Detroit for Nitriding Services?

Alpha Detroit stands out as a reliable provider of nitriding services in Australia. Here’s what sets us apart:

• Extensive Experience: Alpha Detroit boasts a proven track record of delivering high-quality nitriding solutions for various industries.

• State-of-the-art Technology: We utilise advanced nitriding furnaces and precise temperature control systems, ensuring consistent and optimal results.

• Customised Solutions: Alpha Detroit recognises that every project has unique requirements. We work closely with clients to tailor nitriding parameters to meet specific needs and materials.

• Commitment to Quality: Alpha Detroit adheres to rigorous quality control procedures to deliver consistent and dependable results for every project.

Alpha Detroit’s Nitriding Services

With Alpha Detroit, you can start experiencing the benefits of superior corrosion protection and unlock the full potential of your metal components. Our nitriding services can help manufacturers achieve optimal results and ensure their component’s longevity.

Optimized by: Netwizard SEO