The heat treatment of metals is fundamental to manufacturing strong, reliable, and high-performing components. As industries demand higher efficiency and greater accuracy, companies must innovate to keep pace with changing production standards. Meeting these expectations requires smarter, more automated approaches.

Why Heat Treatment Efficiency Matters

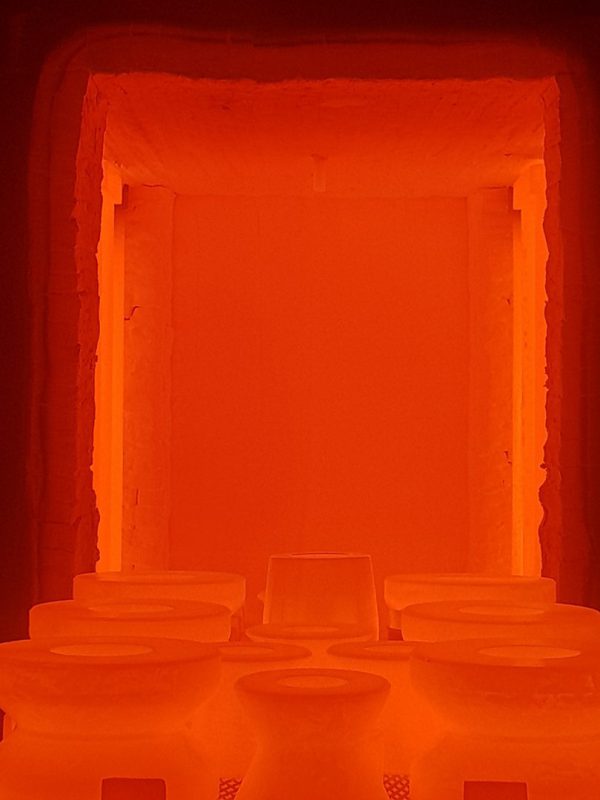

Heat treatment is a series of controlled processes designed to alter the physical and mechanical properties of metals, such as hardness, toughness, and wear resistance. In metallurgy, it plays a vital role in shaping how materials perform under demanding industrial conditions, ensuring they meet precise application requirements.

Efficiency in heat treatment is equally important, as it directly impacts production quality and cost-effectiveness. By optimising processes, manufacturers achieve consistent results, reduce material waste, and enhance overall reliability across a wide range of industrial components.

How Programmable Logic Control Works in Heat Treatment

A Programmable Logic Controller (PLC) is an industrial digital computer designed to automate and monitor complex production systems. When applied to the heat treatment of metals, PLCs allow operators to maintain strict control over critical parameters, such as temperature, holding time, and atmospheric conditions.

Programmable logic controls on both heating and quench cycles ensure optimum heat treatment conditions for a wide range of material, including:

• Hot and cold work tool steels – Achieve precise hardness and durability through controlled heating and quenching.

• Plastic mould steels – Maintain dimensional stability and wear resistance for high-performance mould applications.

• Stainless steels – Enhance corrosion resistance and strength with optimised heat treatment cycles.

• High speed steels – Improve cutting performance and edge retention through accurate thermal processing.

• Low alloyed steel – Increase toughness and fatigue resistance with carefully regulated heat treatment.

Key Benefits of PLC Integration in Heat Treatments of Metal

Integrating PLC technology into metal heat treatment systems delivers a wide range of benefits for manufacturers. This approach not only ensures greater consistency but also enhances workplace safety and drives efficiency across the board.

Key advantages include:

• Guarantees consistent and repeatable results in the metal heat treatment

• Reduces rejects and improves overall part quality for manufacturers

• Enhances safety by minimising human error and reducing manual intervention

• Provides real-time data logging and quick troubleshooting for process improvements

• Boosts energy efficiency and lowers operational costs, helping businesses use resources wisely

Alpha Detroit Heat Treatment: Your Reliable Partner for Heat Treatment of Metals

For manufacturers seeking exceptional results, Alpha Detroit Heat Treatment is a trusted partner in all aspects of metal heat treatment. Our team provides comprehensive thermal processing and metal hardening services, recommending the most effective methods for each application. With a reputation built on quality workmanship, proven reliability, and industry-leading expertise, we deliver results that meet the highest standards.

Contact us to discuss your specific heat treatment requirements today.

Related Blog Article: How a Heat Treatment Modifies Metal Properties

Optimized by: Netwizard SEO