Alpha Detroit Heat Treatment offers efficient heat treatment with a three-chamber vacuum furnace in Australia, improving industrial processes.

In industrial heat treatment, three-chamber vacuum furnaces are leading the way in delivering precision, energy efficiency, and enhanced material properties. Alpha Detroit Heat Treatment, serving clients across Australia and New Zealand, provides heat treatment processes with these furnace solutions, enabling superior control over temperature, atmosphere, and pressure that results in more reliable and consistent outcomes for a range of industries.

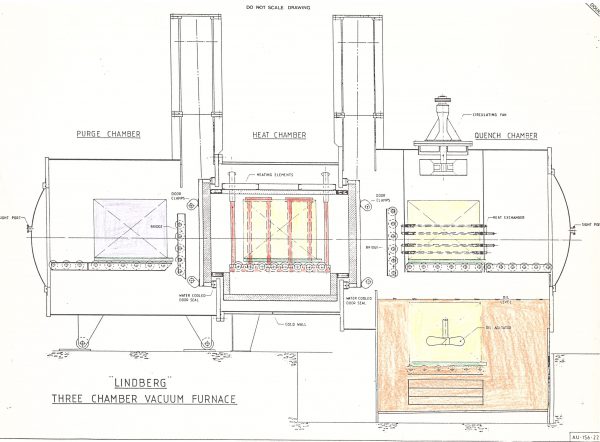

A Quick Look at Three-Chamber Vacuum Furnace

A three-chamber vacuum furnace is designed to perform a variety of heat treatment processes, including annealing, tempering, and vacuum hardening. By creating a highly controlled environment free from air and contaminants, these furnaces enable manufacturers to achieve high-quality results with minimal risk of oxidation or material distortion.

The three chambers—typically including a pre-heating, heating, and cooling chamber—work together to provide optimal temperature and pressure control throughout the heat treatment process.

Transform the Future of the Heat Treatment Process

Here are some ways three-chamber vacuum furnaces are revolutionising the heat treatment industry.

• Enhanced Precision and Quality Control: Three-chamber vacuum furnaces provide superior temperature uniformity and precise control over the cooling rate, ensuring that components are treated to exact specifications. This level of control prevents overheating or uneven heating, reducing the risk of material distortion and ensuring a higher-quality final product. The ability to eliminate air from the furnace chamber also prevents oxidation, surface scaling, or other contamination that could compromise the integrity of treated materials. With a vacuum atmosphere, parts are heated in a much cleaner environment, enhancing the surface quality of the components.

• Improved Efficiency and Energy Savings: Energy consumption is a significant concern for manufacturers, and three-chamber vacuum furnaces offer an efficient solution. These furnaces are designed to minimise heat loss by utilising a combination of vacuum insulation and advanced heating technology, which results in lower energy costs during operation. The three-chamber design improves efficiency by optimising the heating and cooling phases. The preheating chamber helps gradually bring materials to the correct temperature, reducing energy waste during this initial stage. The separation of cooling and heating phases makes sure that heat is applied only when necessary, further improving energy savings and extending the lifespan of the furnace itself.

• Reduced Environmental Impact: As industries around the world move towards more sustainable practices, three-chamber vacuum furnaces are emerging as an environmentally friendly solution. The absence of oxygen in the furnace chamber not only prevents oxidation but also reduces the emission of harmful gases typically associated with traditional heat treatment processes. This leads to cleaner operations and lower carbon footprints, making them an attractive choice for businesses committed to sustainability.

The Process of Heat Treatment with Alpha Detroit

Three-chamber vacuum furnaces are shaping the future of heat treatment by offering unparalleled precision, efficiency, and versatility. As industries demand higher-quality products with better performance characteristics, these furnaces provide the means to achieve those results while also reducing energy consumption and environmental impact.

Whether in aerospace, automotive, medical, or other high-precision sectors, the three-chamber vacuum furnace is poised to play a key role in advancing manufacturing technologies and ensuring that industries meet the growing demands of the modern market.

For a successful heat treatment process with three-chamber vacuum furnaces, partner with Alpha Detroit Heat Treatment today.

Optimized by: Netwizard SEO